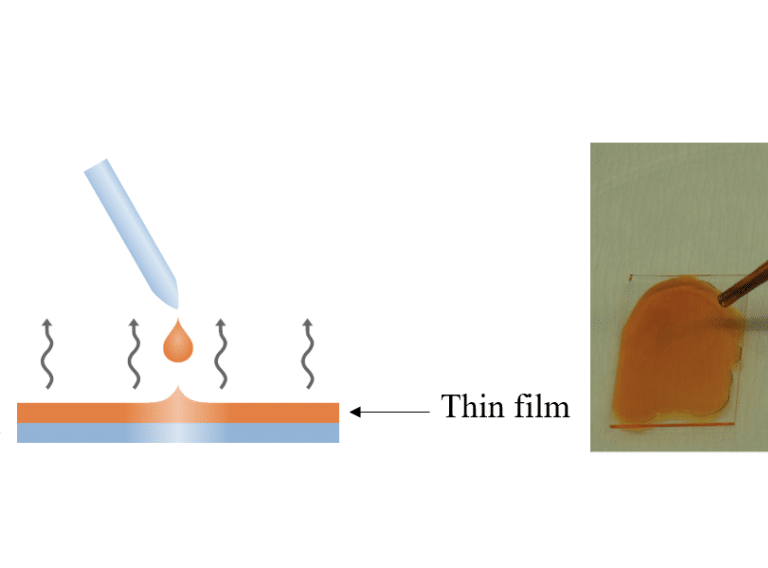

drop casting method

Multiple droplets formed using this method provide a distinctive environment to control the shrinkage direction and the evaporation rate of the droplets Liu et al 2014. Drop-casting method is caused by the unbalanced surface tension of solutionsubstrate solutionair and airsubstrate interfaces enabling film preparation without assistance of depositing apparatus29Apart from conserving time and materials the drop-casting method is in principle much more like an industry-relevant coating processes especially.

Thin Film Processing Method Part 1

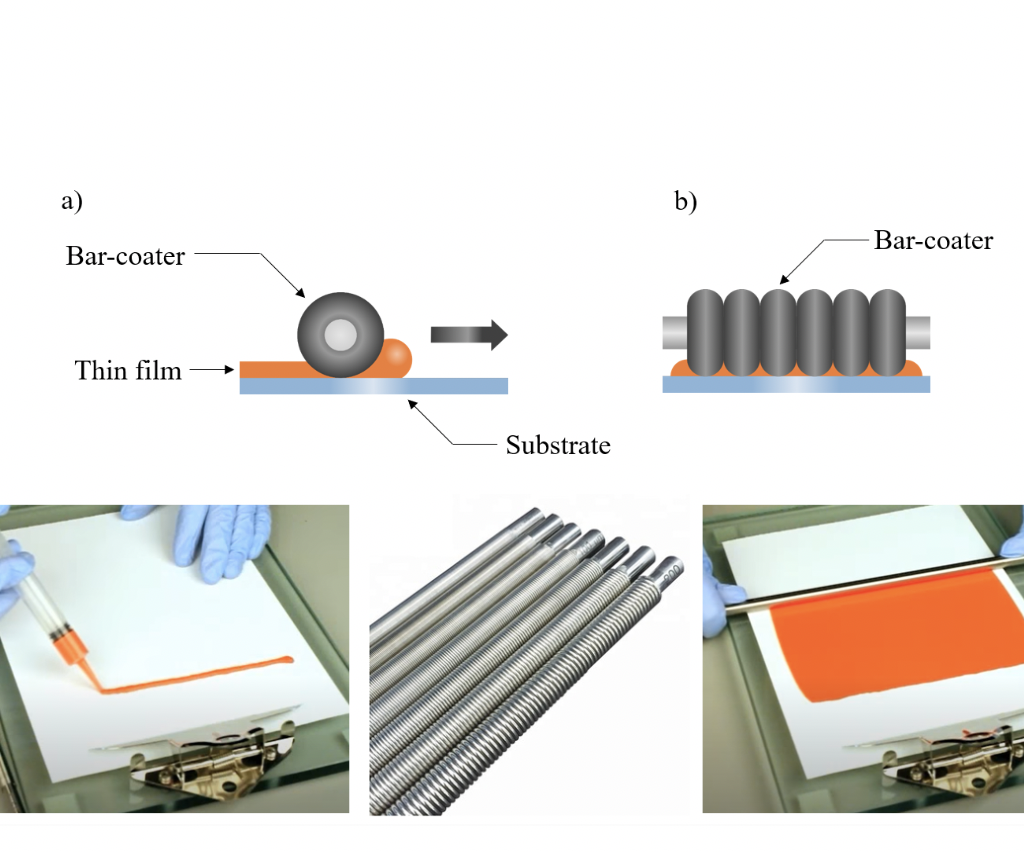

There are several factors that should be considered when selecting a casting material eg desired weight appearance durability texture cost timing.

. Thin Films Drop Casting Method 103390s21134415 To fabricate nanocellulose-based films CNF TOCNF and TOCNF with glycerol TOCNFG were dispersed in water and applied on polyimide substrate with digital electrodes to form self-standing thin. In solvent casting and particulate leaching a polymer is dissolved in an organic solvent. Drop-casting is a simple alternative method for film formation that is more closely aligned to industry-relevant coating processes.

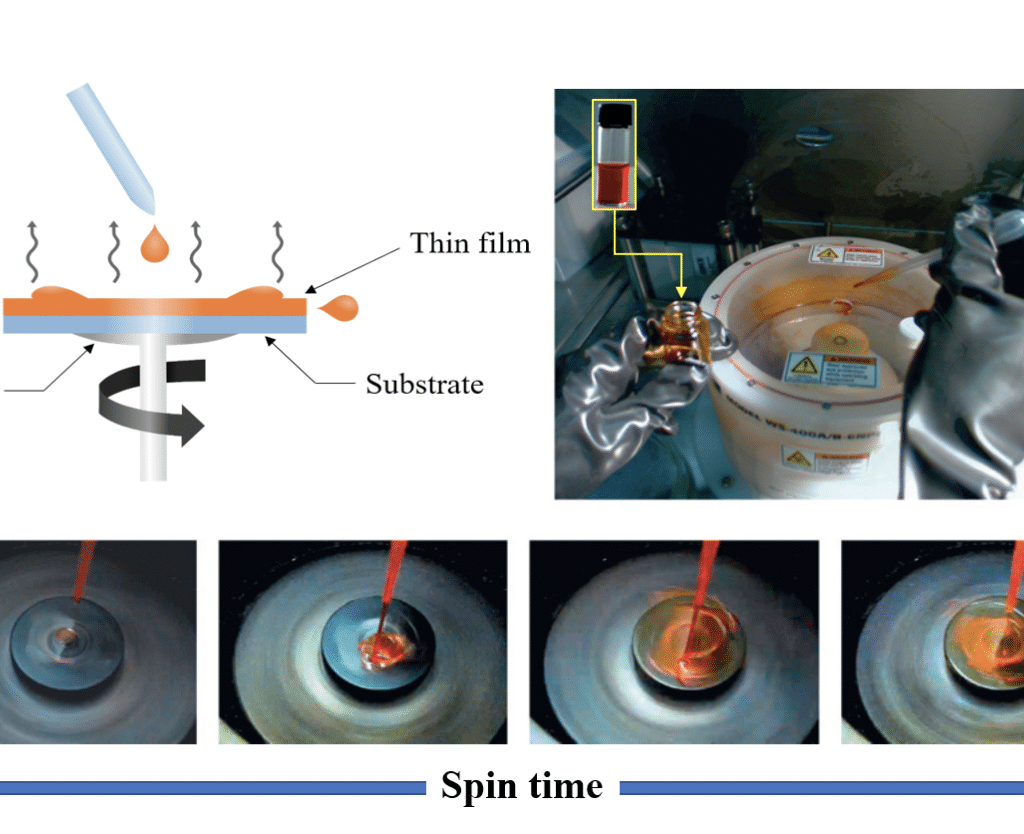

This drop-casting technique not only consumes the less amount of precursor solution but also eliminates the high-temperature annealing as compared with those of spin coating. For example it can be cast onto a glass plate to produce a membrane or in a three-dimensional mold to produce a scaffold. Drop Casting Dropping of solution and spontaneous solvent evaporation Evaporation Dropping Substrate Film thickness.

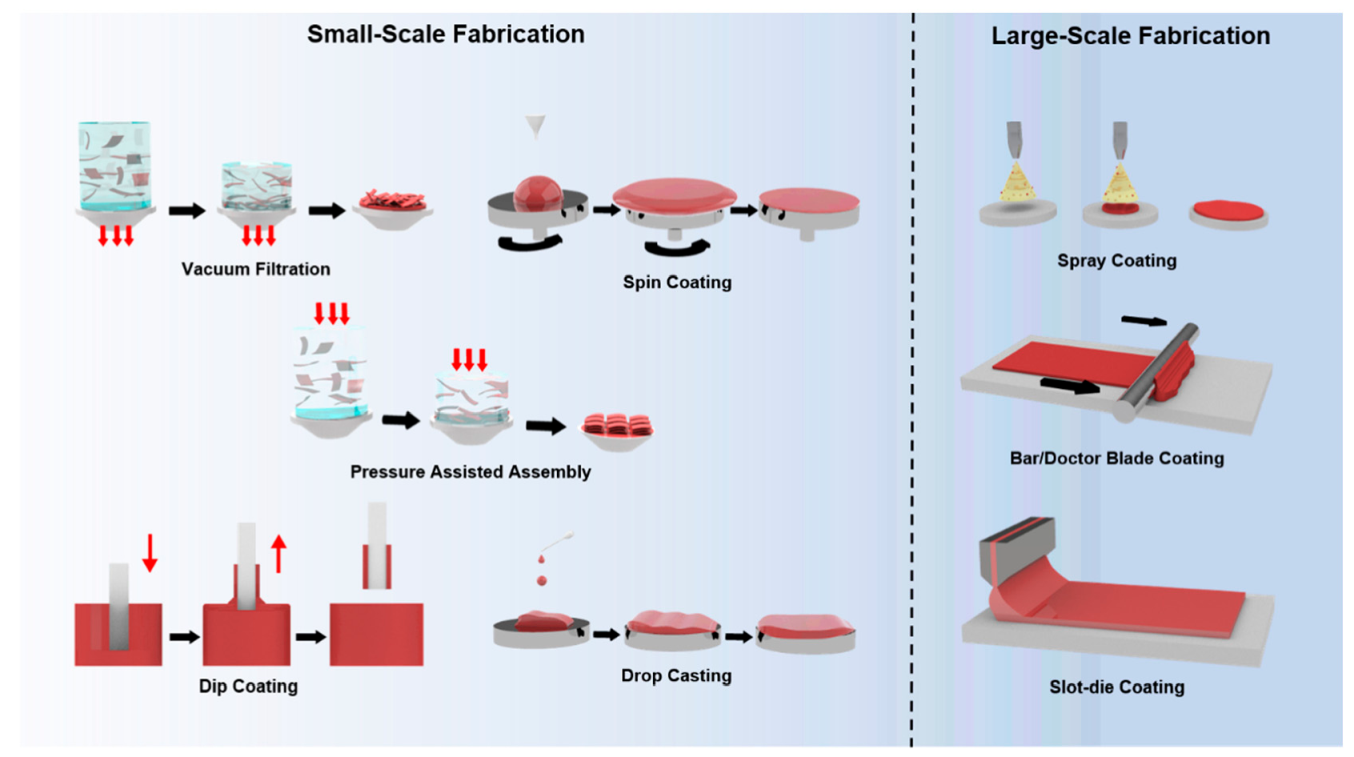

What is drop casting method. Drop Casting Method This method is used for the formation of small coatings on small surfaces. Deposition techniques Drop casting Spin coating Dip coating Layer-by-layer.

Sand is cheap plentiful pliable and able to take the heat. Thus drop-casting is more controllable than spray coating although its application is limited to small-area films and coatings. The self-spreading in the drop-casting method is caused by the unbalanced surface tension of solutionsubstrate solutionair and airsubstrate interfaces enabling film preparation without assistance of depositing apparatus.

How do you cast a thin film. The mixture is shaped into its final geometry. Particles mainly salts with specific dimensions are then added to the solution.

Since the Toluene is volatile it dries very quickly. Substrate Substrate solution concentration. The scientists developed a more controllable coating technique.

In a film-casting process a web of thin film is extruded onto a chilled highly. You need not put Inside the oven. 1600 to 1046 BC.

Recently scientists developed a multiple-droplet drop-casting method for the fabrication of coatings and thin solid films. The impingement of a solution drop onto a substrate in a simple process called drop casting usually results in spreading of the liquid solution and the formation of a non-uniform thin solid film after solvent evaporation. This method is advantageous since the thickness of the polymer-coated film on the electrode can be known from the original concentration of polymer solution and droplet volume.

For small substrates 1 cm 2 an easy and tunable deposition method is drop-casting spreading a nanoparticle dispersion over a substrate and allowing it to dry under controlled conditions ie. One of these factors is the casting method. Substrate Substrate solution concentration Very simple No waste of material X Limitations in large area coverage X Thickness hard to control X.

You should completely fill up the glass slide with the solvent and then just keep Inside the dersicator. Sand casting is the most common method used for metal casting. Spray coating is a commercial and low-cost technique for the fabrication of large-area coatings and thin films but it is a.

Drop-casting is a simple alternative method for film formation that is more closely aligned to industry-relevant coating processes. In principle film thickness depends on the volume of dispersion used and the particle concentration both of which can be easily varied. Drop coating The thickness of the film obtained is directly proportional to the concentration of the nanocomposite solution or suspension.

It requires a very small amount of solvent. Drop-casting is another simple and low-cost deposition method for the fabrication of small-area films3 Drop-casting relies on the release of large droplets with controlled sizes and momentum that spread and wet the surface upon impact. It is manufacturing process at least three thousand years old.

The first evidence of clay casting comes out of China during the Shang Dynasty c. It is no wonder this process is still so popular. In the present work drop-casting was used to prepare films for screening two-dimensional Ruddlesden-Popper 2DRP metal-halide perovskite formulations for potential utility in PSCs without additional processing steps such as inert-gas.

When these MCs are configured into photodetectors they exhibit superior device performance which is in distinct contrast to the one of spin-coated counterparts. Drop-cast is the formation of a thin solid film by dropping a solution onto a flat surface followed by evaporation of the solution. Langmuir-Blodgett Spray coating Drop Casting Dropping of solution and spontaneous solvent evaporation Evaporation Dropping Substrate Film thickness.

This method is easy and fast but the film is not uniform in thickness.

Figure 3 From Comparison Of Drop Casting Vs Spray Pyrolysis Mwcnts Technique For Surface Modification Based Interdigitated Electrode Semantic Scholar

Drop Casting Method To Screen Ruddlesden Popper Perovskite Formulations For Use In Solar Cells Acs Applied Materials Interfaces

Solvent Casting Technique Drop Casting Method Dip Coating Technique Film Casting Technique Polymer Coatings Technologies And Applications

Formation Of Uniform Reduced Graphene Oxide Films On Modified Pet Substrates Using Drop Casting Method Sciencedirect

Typical Coverage Of Graphene Resulting From Drop Casting A Dispersion Download Scientific Diagram

Nanomaterials Free Full Text Fabrication Techniques For Graphene Oxide Based Molecular Separation Membranes Towards Industrial Application Html

Sketch Of The Drop Casting Process Is Depicted Download Scientific Diagram

Perovskite Deposition Using Drop Casting Technique 99 Download Scientific Diagram

Drop Casting Method To Screen Ruddlesden Popper Perovskite Formulations For Use In Solar Cells Acs Applied Materials Interfaces

Perovskite Deposition Using Drop Casting Technique 99 Download Scientific Diagram

Pdf Fabrication Of Silica Pmma Composite Based Superhydrophobic Coating By Drop Casting Method Semantic Scholar

Thin Film Processing Method Part 1

Schematic Representation Of The Drop Casting Technique Used To Deposit Download Scientific Diagram

Schematic Diagram Of Thin Film Fabrication A Drop Casting B Spin Download Scientific Diagram

Thin Film Processing Method Part 1

Sequential Drop Casting Procedure Followed For The Modification Of The Download Scientific Diagram

Controllable Fabrication Of Oriented Micro Nanowire Arrays Of Dibenzo Tetrathiafulvalene By A Multiple Drop Casting Method Nanoscale Rsc Publishing Doi 10 1039 C3nr05680e

The Drop Casting Method Download Scientific Diagram

Schematic Diagram To Drop Casting Method Download Scientific Diagram

0 Response to "drop casting method"

Post a Comment